We test all our products and don’t rely on just the manufacturer’s testing. We tested 7 different concrete sealers for 16 staining agents, for heat, for scratch resistance and for delamination resistance. We also characterized things like cost, ease of use, shelf life, what types of finishes were available (gloss, satin, matte), how long it took to cure, what the samples looked like after they were sealed, if the sealer was color enhancing, if the sealer gave a strong odor or potentially harmful odor, and what information the sealer manufacturer did have.

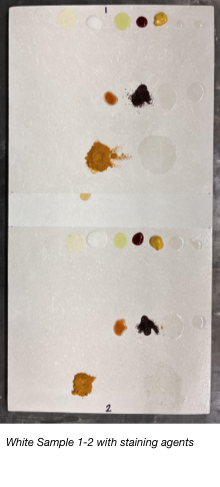

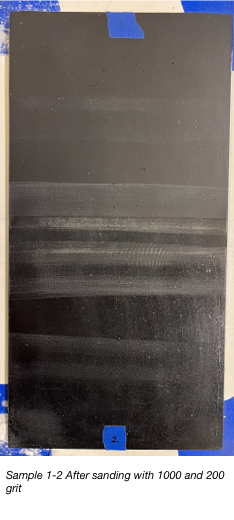

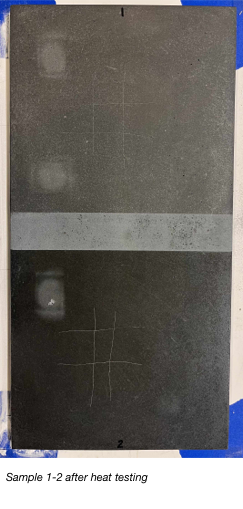

We also tested three different colors of concrete with these 7 concrete sealers. White concrete shows stains more than black concrete does and black concrete typically shows scratches more than white concrete. We used the grey concrete to test for heat resistance and delamination.

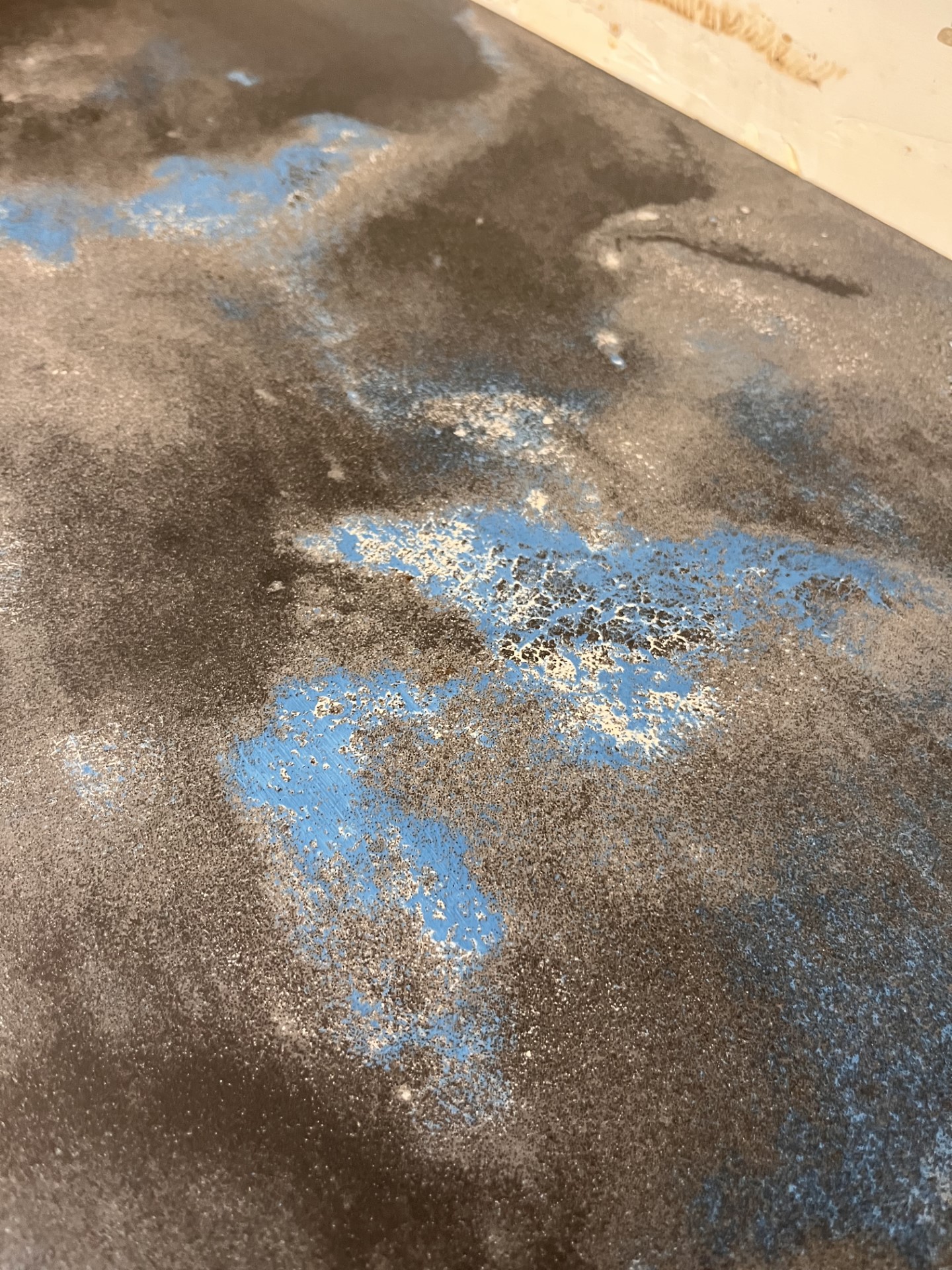

We left each staining agent on the white concrete for 30 hours before trying to remove them with glass cleaner. If we saw stains present after 30 hours and after cleaning with glass cleaner, then we tried bleaching the stains out. We wet a paper towel with bleach and covered each stain with a cup to keep the bleach wet overnight.

We tried to clean the remaining stains with glass cleaner again after bleaching. If the stains still remained we went a step further and tried to wet polish the stain out. Each step of this process we rated in a separate category and each characteristic, we also rated. Then we put all the information into a huge spreadsheet and added all the category scores up and found our winner. We don’t need to hide which concrete sealer we use or why we chose it. From time to time, we may test new sealers but we always do our own testing before putting it on client’s work.

We proudly use Omega from the Concrete Countertop Institute. It is a water based concrete sealer that is environmentally friendly and performed the best in our testing.